In the agriculture community there are terms that get used interchangeably but don’t mean the same thing. Terms such as water buffer, water conditioner and water acidifier can cause some confusion for farmers, if used incorrectly. When dealing with agriculture chemicals, these differences can be the difference between an expensive chemical working or not working. Do you know the key differences among these terms? Read more about how you can distinguish the correct meanings and apply the correct usage to your agricultural needs.

What is pH?

pH is a scale used to describe how acidic or basic an aqueous (liquid or ie.water) solution is. The pH scale ranges from 0 to 14 with 7 being neutral. Anything with a pH less than 7 is considered acidic while solutions with a pH greater than 7 are basic or alkaline (some refer to it as sweet).

Water Buffers

A water buffer is designed to hold the pH of a solution that is stable while adding other chemicals or water to the solution. Buffers work by substituting a strong acid or base with one that is weaker. Water buffers play an important role if you need to add water to the final solution or if there is a chance the water will evaporate from the final solution before or during application. And while buffers are great at holding the pH at a certain level you are not likely to see a lot of change in overall pH level.

Water Conditioners

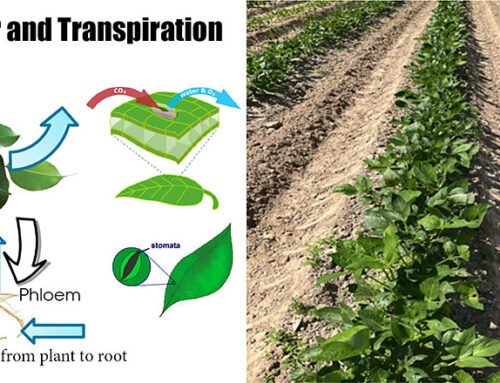

Water conditioner is a broad term for anything that changes the water quality in some way. A perfect example of conditioner is a water softener. Softeners work by removing minerals such as zinc, iron and manganese from the water supply. Water distillation carbon filtering and reverse osmosis are other types of water conditioning. These processes help soften the water and may decrease the pH levels to some degree.

Acidifier

An acidifier is a chemical used in a spray solution that effectively lowers the pH of a solution or make it more acidic. Lowering the pH with an acidifier will help soften the water more efficiently allowing for a positive effect on the application of pesticides. Commercial chemicals often require a certain pH to be effective. The label will specify if pH is critical. While some chemicals need a lower pH to work, some chemicals need to be applied at a higher pH to keep from burning the plants. Before mixing or applying any product, read the label of any chemical to check for the recommended pH level.

At Organisan Corporation, understanding the pH of a mix is the most important element of our technology. It is so important because our products only work properly when the pH is at 5.0 or below. If a customer does not adjust the pH to the correct level, we’ve witnessed a number of problems including clogged spray lines to various undesirable results.

First, and as we refer to as the 11th Commandment around our company, thou shalt always read and follow the label directions. As a consultant for over 50 years, I’ve heard how it should “really” be done, or how so and so mixed it. I’ve also had customers want to tell me that we don’t need to pay attention to those tiny, sometimes hard to read instructions on the labels. How many times have you heard someone say, “oh it’s just there because they have to put something on there”? I’ve observed firsthand the discrepancy that happens when someone alters the instructions and chooses to alter the pH of a mix with a water conditioner vs an acidifier. Unfortunately, it has cost them a pretty penny many times! We add the instructions to our products for a reason.

As a professional, it is in our code to honor and respect the labels of products. As a lifelong Agronomist, Horticulturist and a 50-year veteran Consultant, I encourage you and expect you to read the instructions and follow the directions specifically when dealing with the pH of a mix.

Most recently, I’ve been talking a lot about why people shouldn’t use a conditioner or buffer to lower the pH when using our chitosan-based technology. The primary reason is that those products often contain extra or unique components in them that may not be conducive to the overall mix. Water Buffers often have bicarbonates added and even if you do get the pH to a “5”, it doesn’t always guarantee the outcome. Our products are highly sensitive to the pH level, but most importantly, we require a clean method of managing the pH.

Several years ago, we kept getting calls from customers who confirmed with documentation that their pH was at 5 or below (a requirement of using our OII-YS technology), but they were still having clogging issues. It wasn’t until we went on site and walked through their process that we learned the customer was using a pH reducer that had unidentified additives. Those additives worked in direct conflict with our primary material, chitosan.

Another conflict we found through the years is when farmers attempt to use phosphorous acid to modify the pH. Again, using phosphorous acid is a common practice to reduce pH, but many forms include phosphates that will interfere with the chitosan technology. Therefore, to remove these conflicts and to ensure a positive outcome, we suggest using a pure form of Citric Acid.

Our final reminder on this subject, aka the 12th Commandment, is we need everyone to remember how important the mix order is to the final product. Last year, we had a situation in Utah where the customer was using a phosphorus acid to lower the pH, but in addition, he was adding more to the mix after putting in our OII-YS. It’s very important that our technology is the final element added your mix. In addition, and perhaps even more important, you must check the pH just before adding any of our products. Adjust if necessary, but it must be at 5.0 or lower to be successful. In his case, we were able to adjust the mix order and he was able to have a successful outcome. This order of entry is not a suggestion, it is a requirement. By doing so, you will avoid clogs in your tanks, blockages in your lines and jelly mixes.

Chitosan success is simple. Follow instructions, use a pure Citric Acid like our CitriSan, check your pH, and mix in our chitosan-based technology products last. Then, apply as directed and watch your plants grow into healthy and happy products that far exceed your expectations – Believe the Unbelievable!